Ultrasonic Welding Generator And Welding Transducer For Welding Masks

Product Details:

Ultrasonic Welding Generator And Welding Transducer For Welding Masks Price And Quantity

- 2200.00 - 3500.00 USD ($)/Piece

- 1 Piece

Ultrasonic Welding Generator And Welding Transducer For Welding Masks Trade Information

- 200 Piece Per Day

- 5-7 Days

Product Description

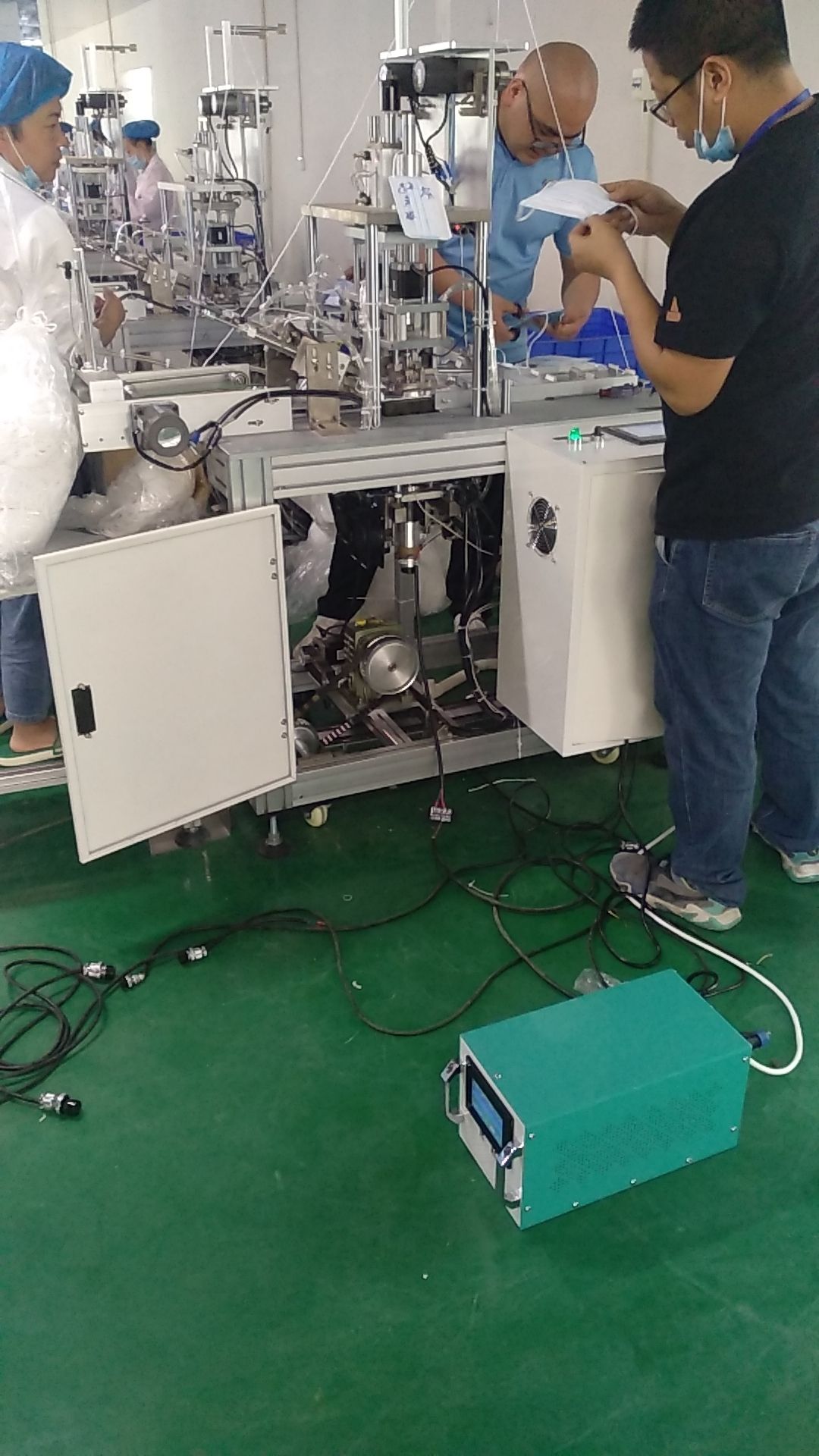

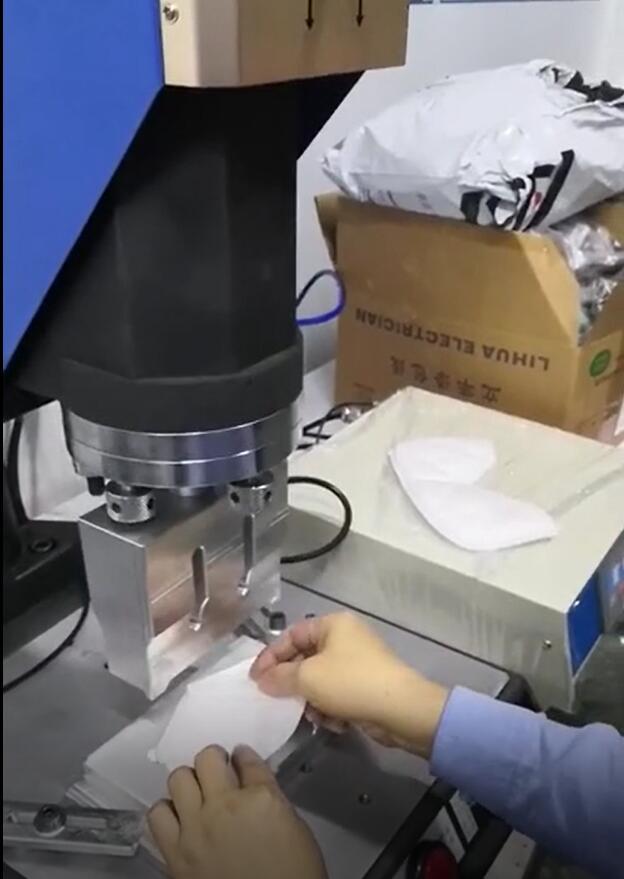

20khz 2000w Ultrasonic Welding Generator And Welding Transducer For Welding Masks

1.1 Introduction

The intelligent SD-UG2500 ultrasonic generator of plastic welding machine has the advantages of compact structure, simple and elegant appearance, easy operation, flexible movement, and easy maintenance. The whole circuit is independently developed by our company.Adopted American TI DSP283 series CPU has the characteristics of wide frequency tracking range, high frequency tracking accuracy, large instantaneous ultrasonic energy output, strong force, fast response, high control accuracy, and strong anti-interference ability.

1.2 Application field

Ultrasound(20khz 2000w ultrasonic welding generator and welding transducer for welding masks) has a very wide range of applications. Generally, we are familiar with being used in medicine and the military. Among them, the industrial field is also widely used. Such as ultrasonic cleaning, ultrasonic flaw detection, ultrasonic grinding and polishing; ultrasonic welding is commonly used for welding, rivets, implant molding of engineering plastic products such as ABS, PC, PS, PA, PP, PET, acrylic, etc .; automotive parts, mobile phone shells, musical instruments , Headphones, chargers, toys, electronic watches, folders, kettles, mobile phone batteries, medical parts, etc.

1.3 Features

1. Using 4.3-inch color LCD touch screen, friendly man-machine interface, easy to set up and save debugging time.

2. Adopt American DSP283 series intelligent chip control, find frequency and track frequency are fast, anti-interference is strong.

3. Two modes can be selected: constant wave and intermittent wave.

4. Infineon IGBT scheme design, high power, stable,reliable and long life.

5. One-click to find the screen is convenient and fast.

6. Multi-protocol can be choosed: RS485 or CAN, which can be compatible with fully automatic system.

7. Overvoltage and overcurrent protection

8. The cabinet is made of 1.5-thick cold-rolled plate spraying process, which is very durable.

9. The weight of radiator overall shape is about 2KG, good cooling performance.

10. Pure copper transformer, sufficient power and high efficiency

1.4 Parameters

1. Dimensions: Length380mm * Width205mm * Height202mm

2. Net weight of host 6Kg

3. Output power: 100-3200W

4. Display: 4.3 inch high resolution color LCD touch screen

5. Working temperature: -20 +65 degree

6. THD<0.2%

7. Input power facto >80%

8. Working frequency: 14-30KHz

9. Working power: AC190-AC240V 50Hz/60Hz

10. Mold frequency range: 4000Hz(Taking 20KHz ultrasonic as an example, the mold frequency can be automatically tracked at 22500-18500KHz)

11. Automatic frequency tracking accuracy: 0.1Hz

12. Power repeat consistency>97%

13. Remote terminal dynamic response time<10ms

14. communication method: CAN, RS485communication, support standard MODBUS RTU